METALWORKING

Department 130 - Metal working was established in 1998 as a producer of control desks, welding and assembly tables as well as various jigs for car industry.

In 2003, the stamping shop and the welding shop for metal parts processed by the technology of stamping, machining and welding were put into operation.

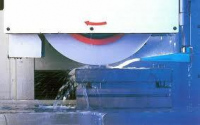

The work is done with hydraulic and eccentric presses of the tonnage of up to 400 T with accessories, resistance-welding machine, welding robots and ordinary machine tools.

Currently, the metalworking department employs approx. 120 workers in a two-shift and a three-shift operation.

Technologies

List and number of presses used in HAUK s.r.o.:

PRESS NO. |

PRESS MACHINE |

|

| L1 | LENP 63A | |

| L2 | LEN 63C | straightener QRM-E 300/4 with feeder SRF-100 through SFR-600 |

| L3 | LEN 63C | straightener QRM-E 300/4 with feeder EVP 300-80 |

| L4 | LEN 63C | straightener QRM-E 300/4 |

| L5 | LEK-160 | straightener QRM-E 300/4 |

| L6 | LE 250/40 | |

| L7 | LEK-250 | straightener QRM-E 300/4 |

| L8 | LEN 63P | straightener QRM-E 300/4 |

| L9 | LE-160 | straightener QRM-E 300/4 |

| L10 | LE-160 | straightener QRM-E 300/4 |

| L11 | LEN 40P | |

| L12 | LE-250C | |

| L13 | LE-250C | |

| L14 | LE-250 | |

| L15 | LE-250C | |

| L16 | LEN 25C | |

| L17 | LEN 63C | |

| L18 | SN2 - 160 | |

| L19 | PRESS BRAKE LO 50 | |

MACHINE TOOLS |

|

| Drill press | BH 32 |

| Drill press | 612A ZMM |

| Drill press | B1316F |

| Pillar drill | BH 32 |

| Drill press | WS 32 |

| Vertical milling machine | CSP1 |

| Milling machine with digital readout | FNGJ 32 |

| Centre lathe | SU 18 |

| Centre lathe | SV 18 RA |

| Centre lathe | SU 18 |

| Flat-surface grinding machine | BPH 320A |

| Flat-surface grinding machine | BPH 320A |

| Flat-surface grinding machine | STUDER RHU 450 |

RESISTANCE-WELING MACHINES |

|

| B1 | Tucker |

| B2 | Tecna 2122N |

| B3 | Tecna 2122N |

| B4 | BP20,22 |

| B5 | Tecna 4626N |

| B6 | Tecna 8005N |

WELDING ROBOTS |

|

| SR1 | Romat 320 CLOOS |

| SR2 | Romat 320 CLOOS |